Temperature and Moisture content are two critical factors that have to be monitored to ensure quality when storing grains.

The process by which most grains deteriorate is exothermic producing heat, water and carbon dioxide.Changes in temperature are therefore reliable indicators of potential quality problems in grain storage systems that can often be averted if operators are aware of the changes.

Living organisms such as mites, insects and microorganisms such as mold and bacteria respire. In dry grains the temperature increase caused by respiration can be reliably detected (known as dry grain heating). Insects that create additional heat and respiration may also create secondary grain infections such as fungi to develop.

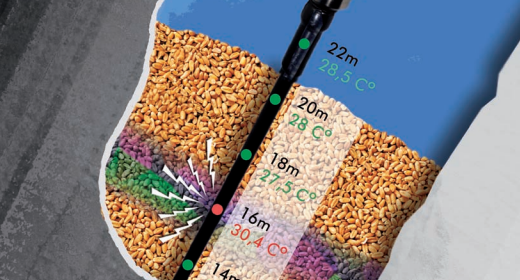

Compared to the expense and difficulty of measuring Carbon Monoxide and Moisture content continuously measuring temperature at regular intervals (e.g. every meter) throughout a grain silo is very easy and relatively inexpensive. When combined with relative humidity data temperature can be used to predict grain moisture content.

To reliably measure hot spots created by spoilage or infestation careful consideration have to be given to the number and distance between temperature sensors. Because most silos do not have temperature measurement build-in as part of the design it has become common practice to suspend multi-point temperature sensors into silos from above.

For more information about how to measure temperature in grains, visualise temperature data and create predictive alarms based on temperature data please contact jacque@visipraxis.com.