How do you know which industrial pH sensor is the perfect choice for your application? The different number of industrial combination pH sensors out there can be overwhelming. Before making an industrial pH sensor purchase, it is crucial to have a better understanding of your application and the conditions the sensor will be enduring while in use. Based off this knowledge you can make a decision on which types of features will be required. Here are some questions you may want to consider:

What is the length of cable required?

This is considered to be the distance between your sensor and the front end of your device, such as a controller, analyzer or transmitter. If the cable length is greater than or 8 meters, you may be required to install a pre-amplifier between both the sensor and controller. A pre-amplifier converts the high impedance mV signal of a pH or ORP sensor to a lower impedance signal which can travel up to 300 meters.

How will the sensor be installed?

It is very important to understand how the sensor will be installed. The two most common installation methods for an industrial pH sensor are: in-line (flow through cell/pipe tee) or submersion assembly. Based off the installation method there may be different pH sensor types and accessories for your application. For example, if you require an in-line pH sensor, a flat surface design may be best suited for your application, as the flow across the sensor acts as a self-cleaning mechanism that will extend the lifetime of the probe.

Is automatic temperature compensation (ATC) needed?

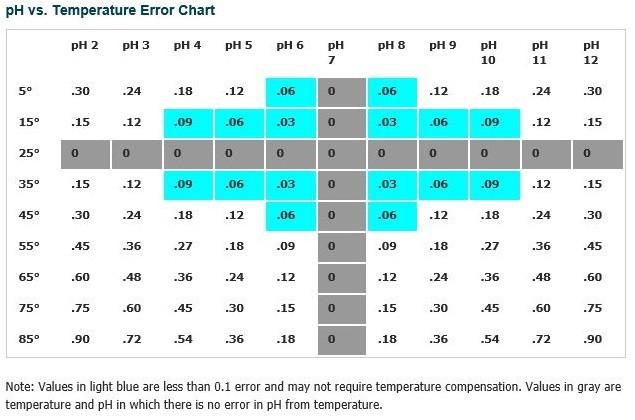

The pH measurement is temperature dependent. If there is an extreme and varying temperature range for your process application, it is likely that the temperature compensation is required for your pH measurement. The desired pH accuracy, process temperature range, and pH measurement range should all be taken in consideration when deciding if an automatic temperature compensation (ATC) is needed. The following chart is extremely useful when making this determination:

What type of instrumentation will be used in combination with the pH sensor?

It is imperative to understand whether the industrial pH sensor will be connected to a controller, transmitter, analyzer, PLC, DCS system, data logger, PC, or any other device. This is important because you want to understand what type of output signal is required from the sensor and if it is compatible with the instrumentation you will be using. If temperature compensation is enabled, it is also important to match up the temperature element (i.e. RTD, thermistor, etc.) embedded in the pH sensor to the temperature requirement of the front end of the device. Sensorex pH sensors can be compatible with most standard pH transmitters/controllers on the market. Sensorex also offers a line of pH transmitters and controllers

What is in the aqueous process that will challenge the pH electrode?

For example:

What is the maximum temperature of the water?

- Extremely high temperatures may damage the materials of the pH sensor.

Are you measuring pure water or is there any hydrofluoric acid present within the process?

- Standard pH sensors will not perform for the long term in these types of environments and will lead to inaccurate pH measurements. For these process environments, Sensorex has specially designed versions of our industrial pH sensors for low conductivity (-LC) or applications where hydrofluoric acid (-HF) is present.

Are there any known ground loop issues?

- With process pH sensors, a ground loop is an unwanted electrical current path, in the system, where stray signals cause interference in the pH measurement. If this is a recognized issue, you will want to use a pH sensor that has a solution ground electrode to handle this stray voltage in the process system. The Sensorex S8000 modular pH sensorhas this as a popular measurement option.

What is your preferred price point for a process pH sensor?

This is always the golden question, but is also important to consider the value in different styles of pH sensors while making your decision.

To assist with weighing features and value versus price, Sensorex has developed a tiered offering based off of application needs that will benefit you while making the best choice when considering industrial process pH sensors.

With answers to all the questions above and help from our application experts, you are now ready to choose the best industrial pH sensor for your process application!

Please feel free to contact us for your Liquid Analysis requirements or visit www.visipraxis.com/ for our Sensorex offering.

Credit: Sensorex